Task

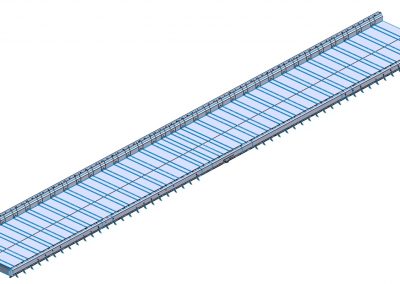

Check the strength of a 12.4 m x 1400 mm sized trough of a vibratory conveyor. Qualitative strength assessment of similar trough from the same product family. Create a well documented dimensioning calculation that allows designer to optimise critical parameters such as suspension units, flexural leaf springs, drive motor size and location, center of gravity and weight of counter mass.

Solution

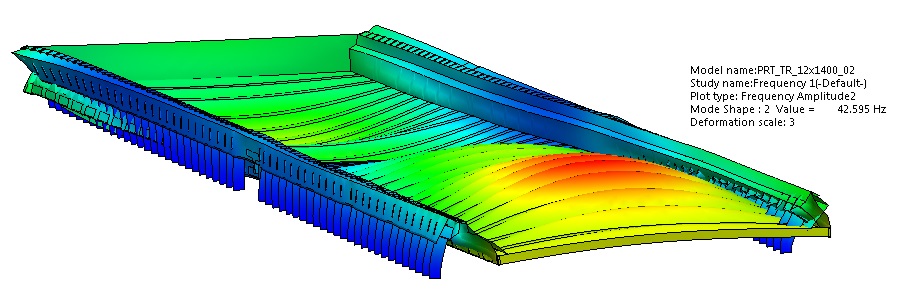

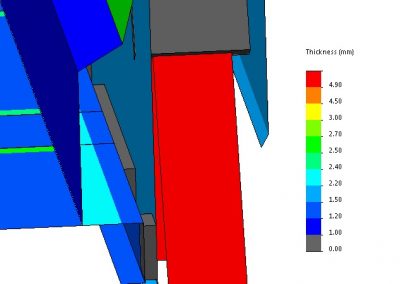

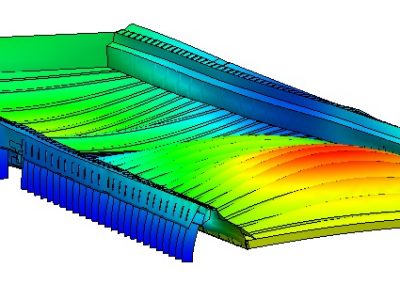

3D surface model for FEM calculation. Modal analysis to avoid resonance ad to provide design suggestions for customer at conceptual phase of the development. The same model was used to check dynamic and static strength of the structure. At the end of the project final geometry was assessed again.

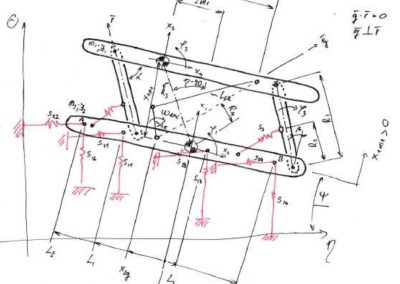

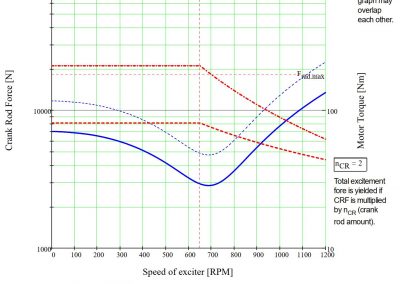

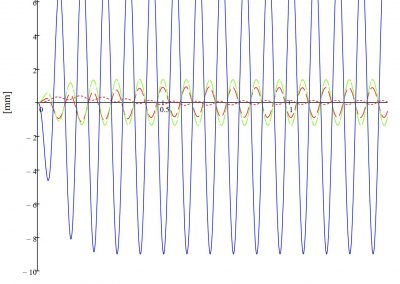

MathCAD document was created to dimension and optimised the vibratory conveyor. 4 DOF plain kinematic model was used to establish Lagrange equations. Optimisation algorithms were set up to determine local minimums for parasitic motions of the system. Calculation provided information for steady state and transients also.